Production flexibility with 3D laser cutting

What does 3D laser cutting offer in the construction of metal dies and sheet metal processing?

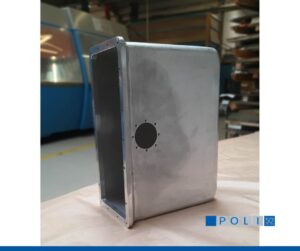

Precision, speed, and cutting quality are certainly the most evident advantages of applying this cutting technology in the production process. In fact, 3D laser technology allows for extremely precise cuts on metallic materials, producing three-dimensional pieces with tolerances within a tenth of a millimeter. The speed of the process compared to traditional methods reduces material waste, optimizes resource use, and decreases production times and costs.

But the production flexibility offered by 3D laser cutting is one of the aspects we most appreciate at Fratelli Poli. Why?

Because this technology in the design and construction of metal dies allows us to create different variants of the same product while keeping costs low for our clients. When new products are introduced to the market, there is often initial uncertainty regarding sales. For this reason, we offer 3D laser blanking, which allows us to define even very complex three-dimensional cutting paths. This way, we can postpone the client’s investment in the blanking mold until the market confirms interest in the product.

In conclusion, 3D laser cutting allows us to offer clients a unique combination of precision, speed, and production flexibility, significantly reducing product development times while simultaneously improving the quality and efficiency of production processes.

Visit our VIDEO section dedicated to 3D laser cutting HERE

Tell us about your projectWrite to us without obligation at info@fratellipoli.it share your project with us. We will be happy to share our expertise and create Dies for your applications |

For further insights into our production technologies, visit the sections dedicated to Cold stamping of sheet metal, alla Progressive dies constructionand Deep drawing dies