Business Productivity: How to Improve It with Cold Metal Stamping

In the realm of industrial production, choosing the appropriate technologies and production processes is crucial to maximizing efficiency and minimizing costs. Thanks to our many years of experience in the die and cold metal stamping sector, at Fratelli Poli, we can offer highly advantageous solutions both economically and technologically.

Advantages of Cold Metal Stamping

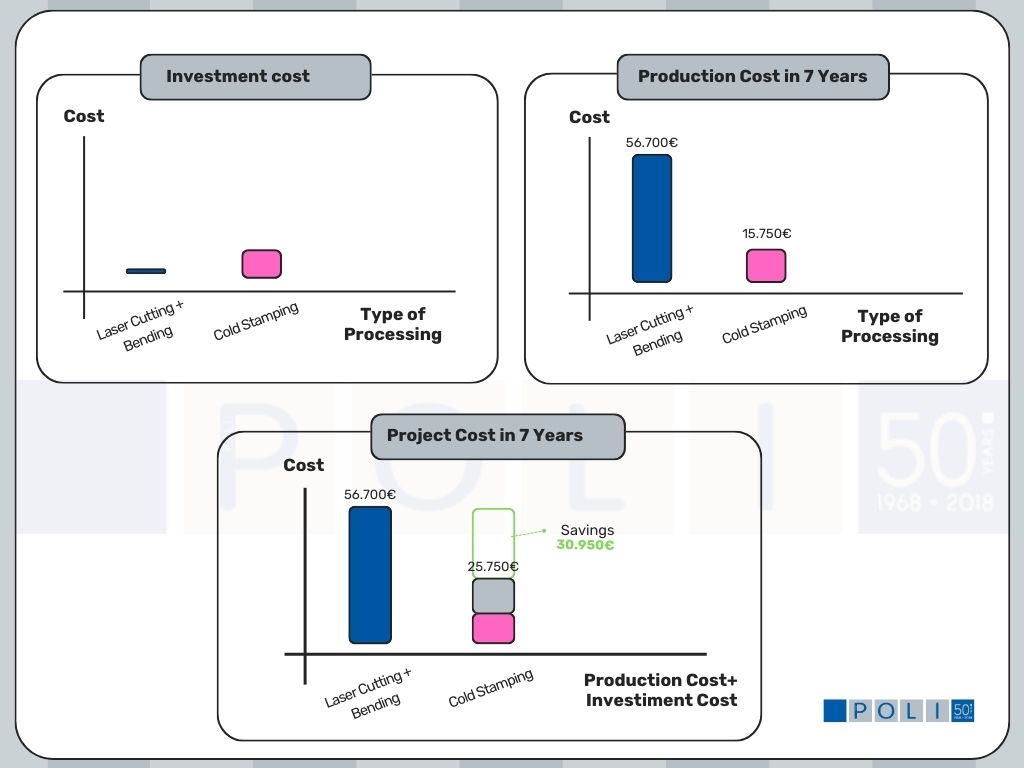

Cold stamping is a metal processing technique that offers significant advantages in terms of cost and efficiency compared to traditional methods like laser cutting and bending. The cold stamping process allows for the production of metal components at a significantly lower cost, due to reduced material waste and fewer necessary production steps.

Lower Costs and Greater Efficiency

By using cold stamping, at Fratelli Poli, we can create components that would traditionally require expensive laser cutting operations followed by bending. Stamping not only reduces waste but also decreases manufacturing costs by producing one part for each stamping, eliminating the need for multiple operations.

Production Flexibility

Another strength of cold stamping is its flexibility. During the process, it is possible to perform additional operations such as threading holes directly on the components. This ability to integrate multiple functions into a single processing cycle further reduces production time and costs.

Customization and Branding

At Fratelli Poli, we also offer advanced customization options: it is possible to print serial numbers and logos directly onto the components during stamping. This eliminates the need for subsequent steps to apply branding or other identifiers, thus reducing labor costs and delivery times while ensuring exceptional branding consistency.

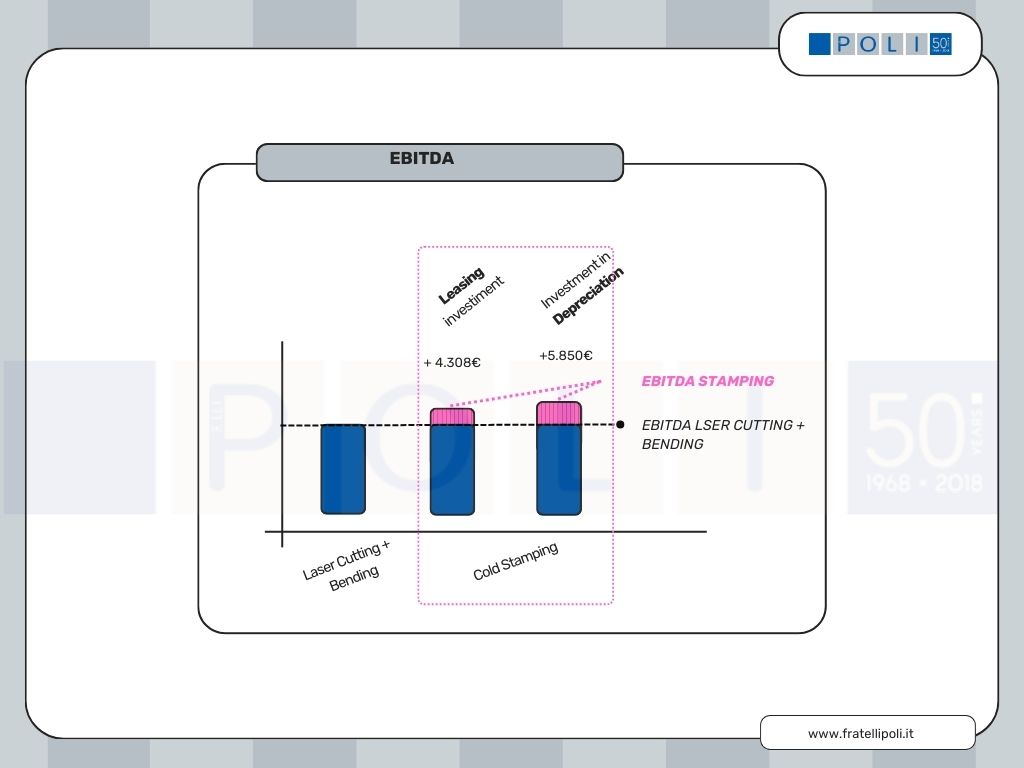

ECONOMIC ANALYSIS: Impact on EBITDA

How can you reduce the production costs of metal components and increase the margins on sold products?

In this downloadable guide, we will explore the advantages of cold metal stamping compared to traditional methods such as laser cutting followed by bending. You will discover how cold stamping can significantly lower production costs through faster cycles, less waste, and superior production efficiency. We will also see how this technology can help increase margins on sold products, providing a quick payback on the initial investment.

Request the PDF for free to learn how to optimize your production and improve your business margins!

Optimizing the Production of Metal Components: Simulation and Cost Analysis

Request the full PDF

Fill out the form below. We will send you via email the in-depth report “Optimization of Production Processes through Cold Metal Stamping.”