Simulating the stamping process to optimize die construction

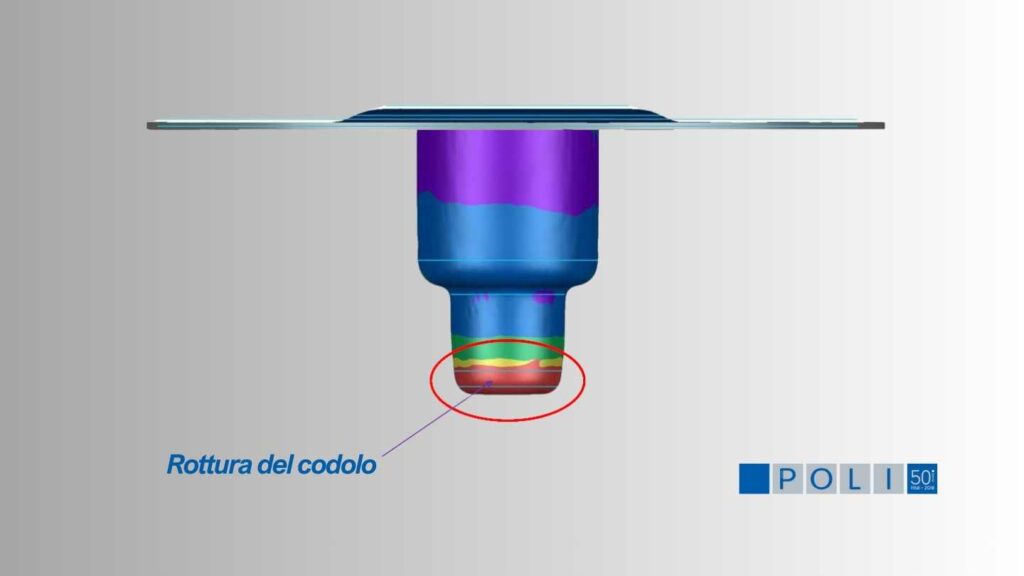

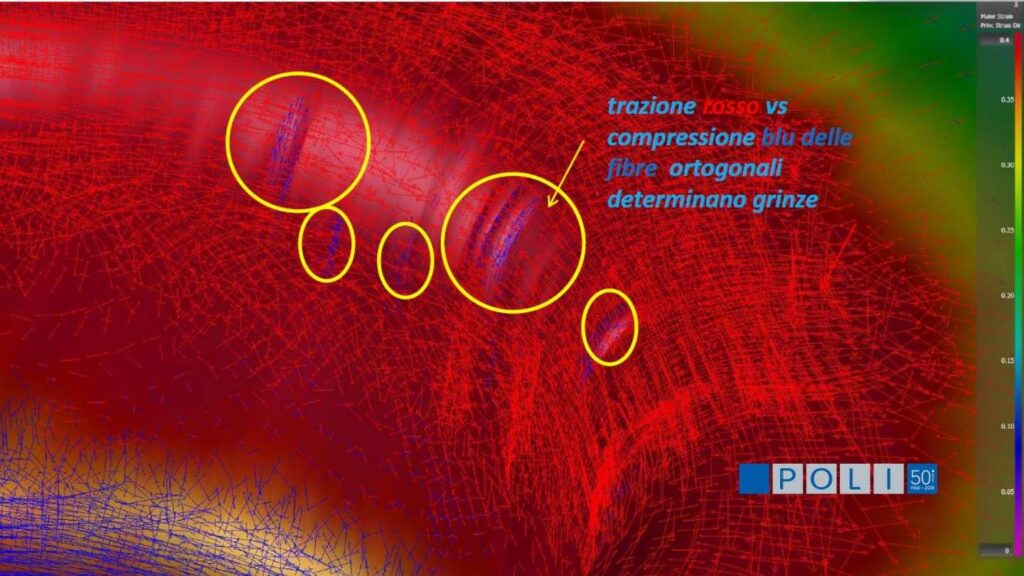

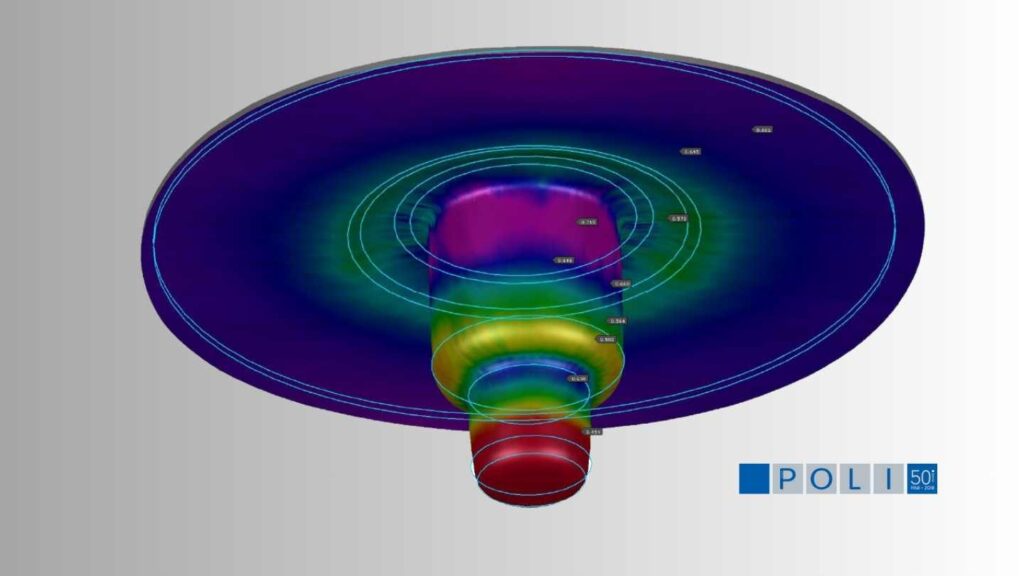

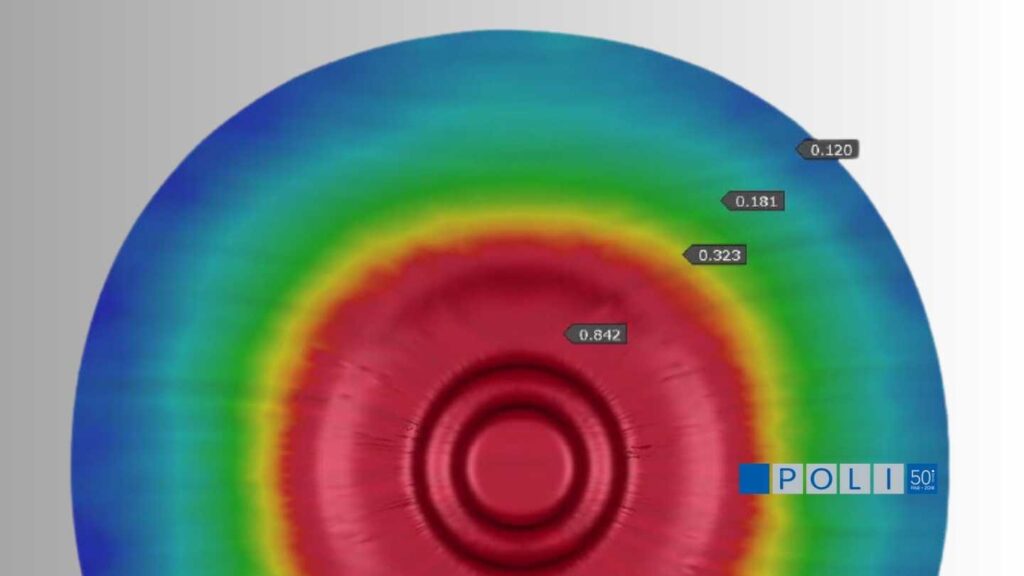

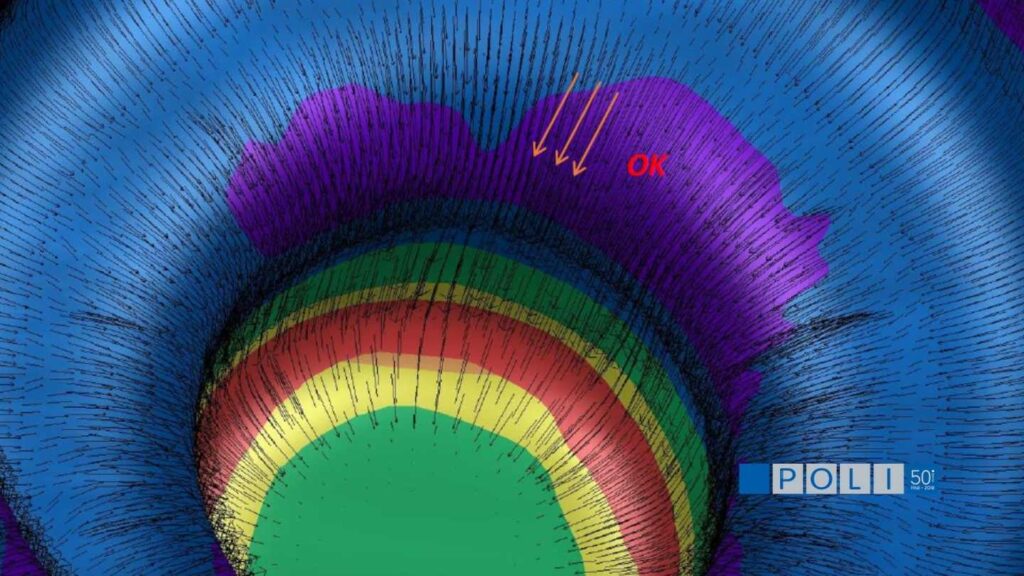

Thanks to simulation at Fratelli Poli, we are able to identify areas of the product that could be vulnerable to breakage, potential critical issues, feasibility, conformity of components to be produced, to propose possible modifications to the geometry. Furthermore, through precise analysis of thickness in different sections of the bottom, we verify if the final values meet the required specifications and established standards.

What is Sheet Metal Forming Simulation?

The sheet metal forming simulation is an advanced process that utilizes specialized software to predict and analyze the behavior of the metal during the forming phase. This technology allows our technical department to virtually simulate the forming process, examining factors such as deformation, stress, material flow, and defect formation.

What are the advantages of Sheet Metal Forming Simulation?

The benefits of preliminary analysis obtained by simulating sheet metal forming processes are:

- Reduction in product development times: simulation allows us to test different Die configurations and process parameters without physically creating prototypes. This significantly reduces product development times.

- Optimization of product design: simulation provides a thorough understanding of material behavior during the forming process. This enables us to optimize product design to ensure maximum strength, durability, and functionality.

- Reduction in production costs: by identifying potential defects or production problems early in the simulation phase, we can make necessary changes to the process or mold design before commencing large-scale production. This helps reduce costs associated with production delays and the need for costly repairs.

- Improvement in product quality: the ability to predict and prevent defects such as wrinkles, tears, or deformations allows us to implement necessary corrections to ensure the highest quality of the finished product.

Tell us about your project.Write to us without obligation at info@fratellipoli.it share your project with us. We will be happy to share our expertise and create Dies for your applications. |

For further insights into our production technologies, visit the sections dedicated to Cold stamping of sheet metal, Progressive dies construction and Deep drawing dies