Why does drawing technology perfectly match the requests of architects and designers?

In the furniture and lighting industries, design and precision of shapes are fundamental. Being unique and innovative in terms of materials often makes the difference. Designers and visionaries of this sector know it very well as they sometimes struggle to turn their brilliant ideas into commercial products.

Currently laser cutting, bending and welding are the most common technologies to give metal complex shapes.

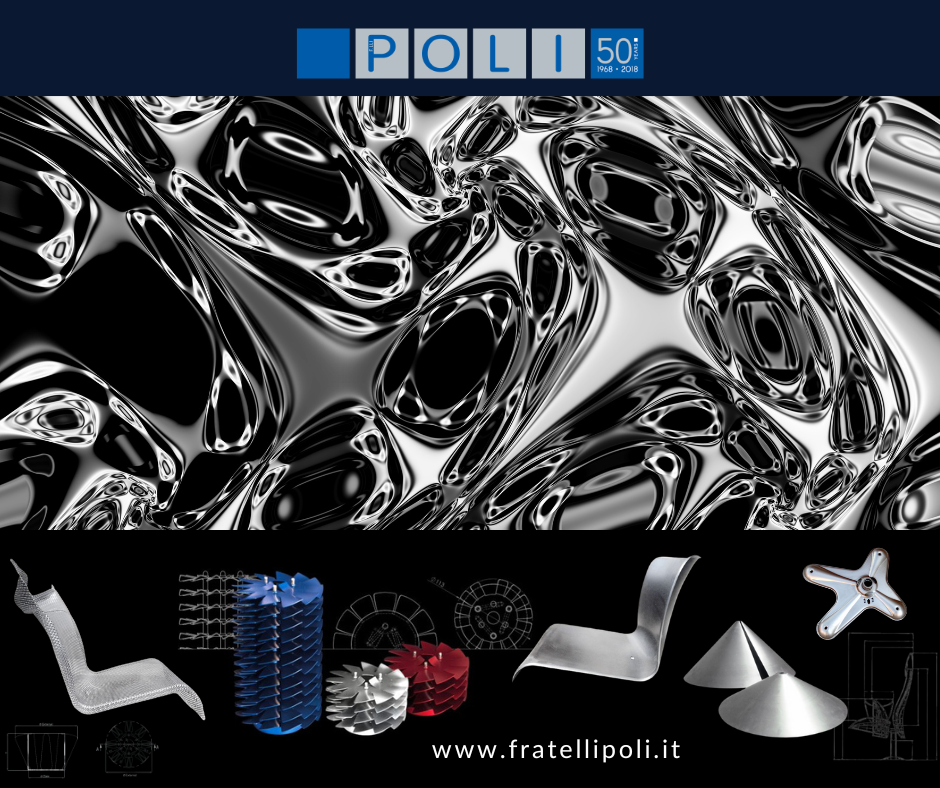

Fratelli Poli has over 50 years of experience in the cold metal stamping and perfectly masters all these technologies.

Where is the added value? The added value lies in producing by deep drawing.

This technology enables to shape flat metal sheet into complex geometries without any welding. In combination with lasercut of 3D-surfaces, Fratelli Poli provides its clients with two specific advantages:

- reduced investment costs for tooling: no need to invest in trimming dies;

- small production batches with minor modifications of openings and holes can be easily produced thanks to the production flexibility of laser

At Fratelli Poli we are not allowed to say it cannot be done!

Further information and a gallery of our projects are available here: Furniture and lighting industries and Drawing dies

Get in touch with us to get a predictive analysis or a free quote Click here