Progressive Die Stamping – Efficiency and Repeatability in Mass Production

Progressive Dies and Cold Metal Forming: Tailored Solutions for Industrial Manufacturing

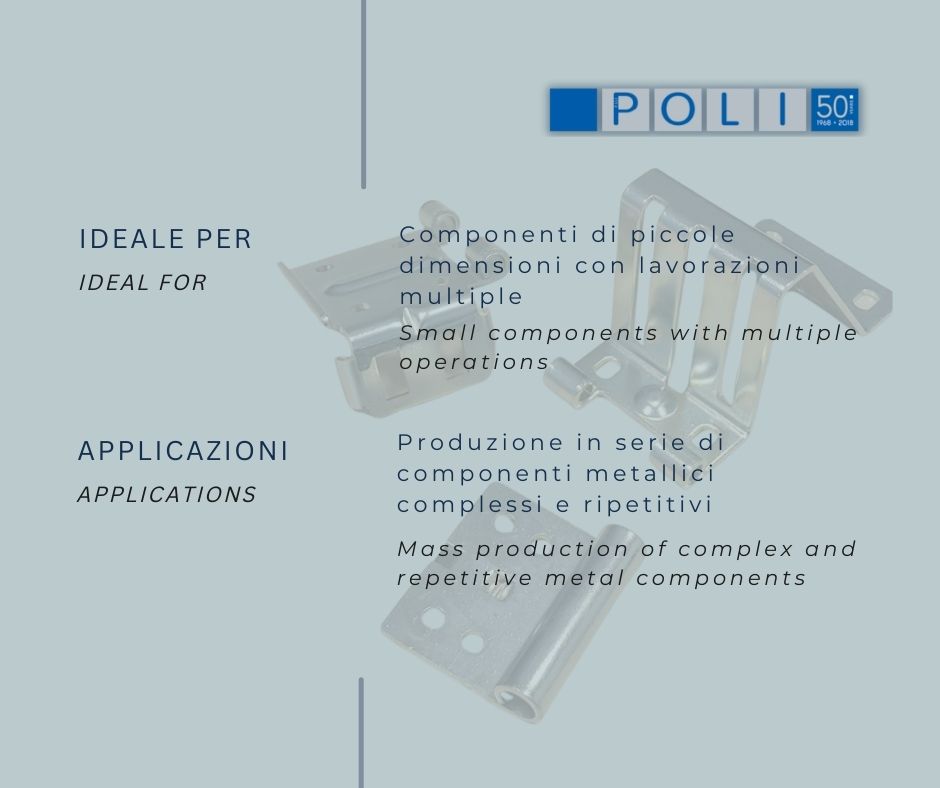

Progressive die stamping is a cold forming technique that enables the automated production of metal components through a series of sequential operations. This technology is particularly suited for mass production of complex and repetitive components.

With over 50 years of experience in the industry, Fratelli Poli specializes in the design and construction of custom progressive dies for various industrial applications. Utilizing advanced software and in-depth knowledge of processing stages, the company develops dies that minimize material waste and maximize durability, while also facilitating maintenance.

Fratelli Poli’s expertise spans numerous sectors, including automotive, medical, food, lighting and furniture , renewable energy, offering customized solutions that meet each client’s specific requirements.

Key Advantages of Progressive Dies:

- High-Speed Production: Each press stroke yields a finished part, ensuring reduced production times.

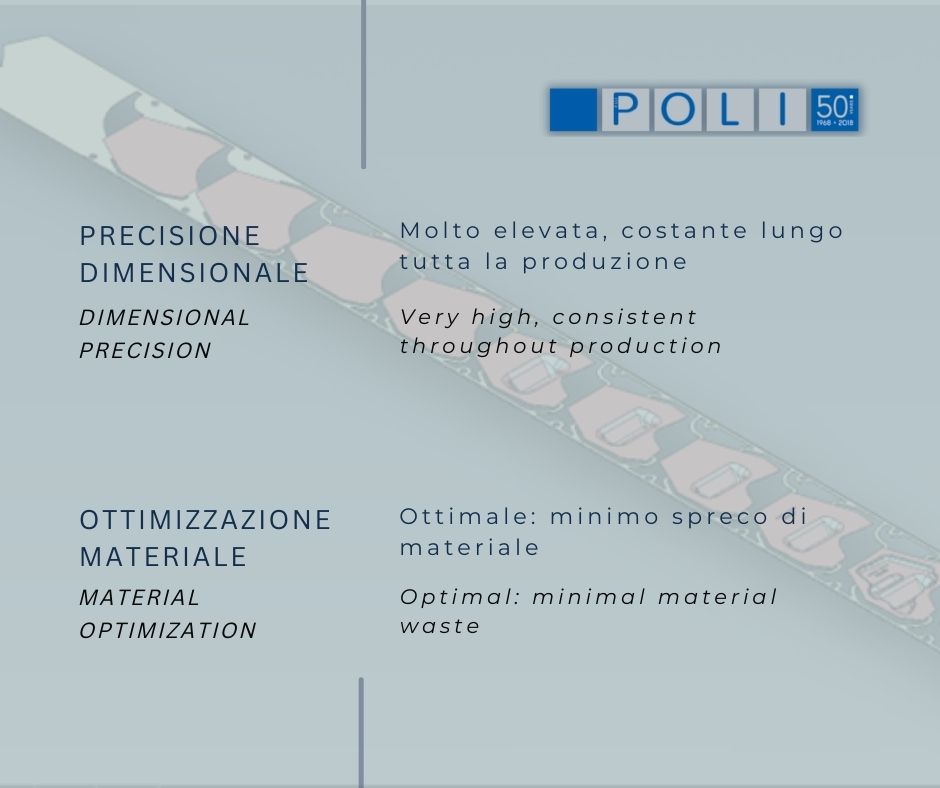

- Consistent Precision: Maintains tight tolerances and dimensional uniformity throughout production.

- Material Optimization: Minimizes waste through efficient sheet metal utilization.

- Reduced Secondary Operations: Integrates multiple processes into a single operation, decreasing the need for post-stamping work.

- Ideal for Large Volumes: Maximizes efficiency and lowers unit costs in large-scale productions.

Therefore, progressive die stamping is the ideal choice for mass production of metal components, offering speed, precision, and high operational efficiency.

Trust in Fratelli Poli

With an integrated approach and cutting-edge technologies, Fratelli Poli positions itself as the ideal partner for companies seeking efficient and customized solutions in cold metal forming. Contact us to discover how we can support your projects from the initial phase to the finished product.

Fratelli Poli: experience, precision, and innovation at your service.