From a production need to a successful partnership

Food Sector: a more efficient production solution with deep drawing die.

The food sector is constantly in search of innovative solutions to optimize production processes, reduce costs, and improve efficiency. In this perspective, F.lli Poli and the client company joined forces to tackle an exciting challenge: the creation of a new way to produce an aluminum tray through the development of a deep-drawing die.

The Challenge

The initial need to optimize production was constrained by the essential technical characteristics of the product itself. It was necessary to preserve and, if possible, improve:

- the ability to contain products for lyophilization in the autoclave area

- the need to support a weight of approximately 8 kg distributed over the entire surface

- the operating temperature resistance of the tray (30 °C)

- the compatibility of the material for food use (Aluminum AlMg3 5000)

The Innovative Solution

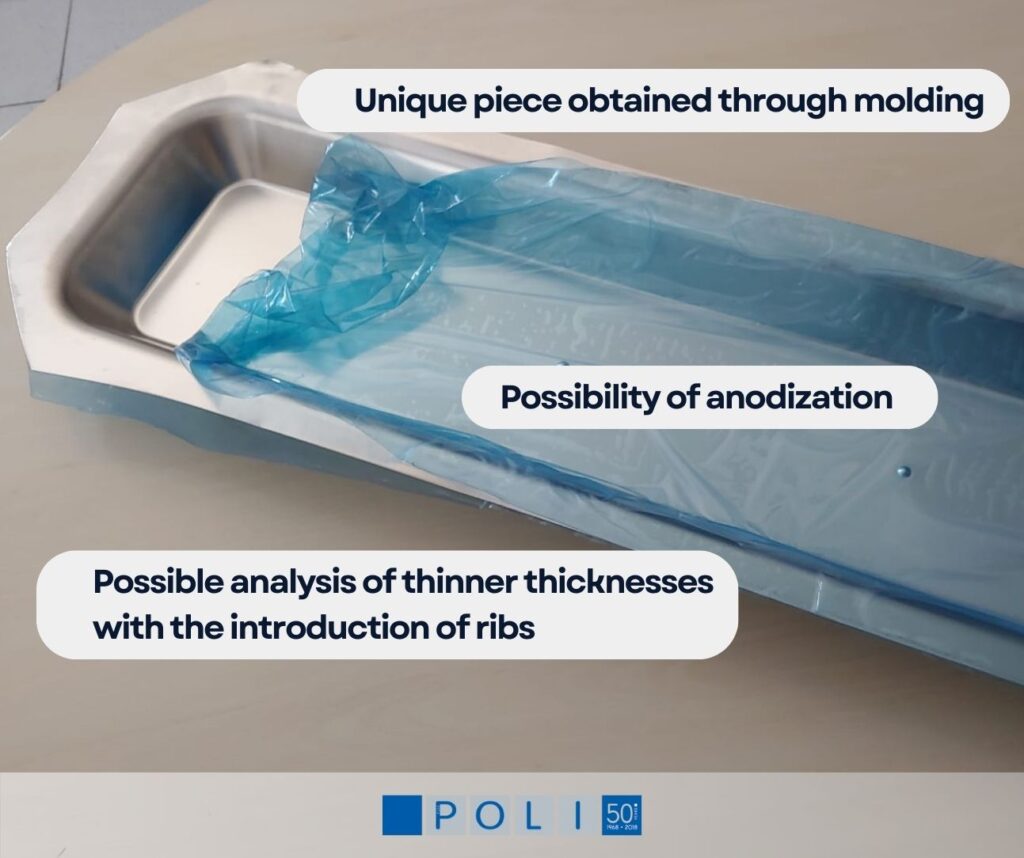

After careful analysis, F.lli Poli proposed the use of deep drawing stamping. Why this technique?

Because deep drawing die allows for the creation of complex and detailed geometric shapes of the tray without welding. Previously, the product was made by welding two identical trays, and the dividing partition of the loading surface could create emptying difficulties.

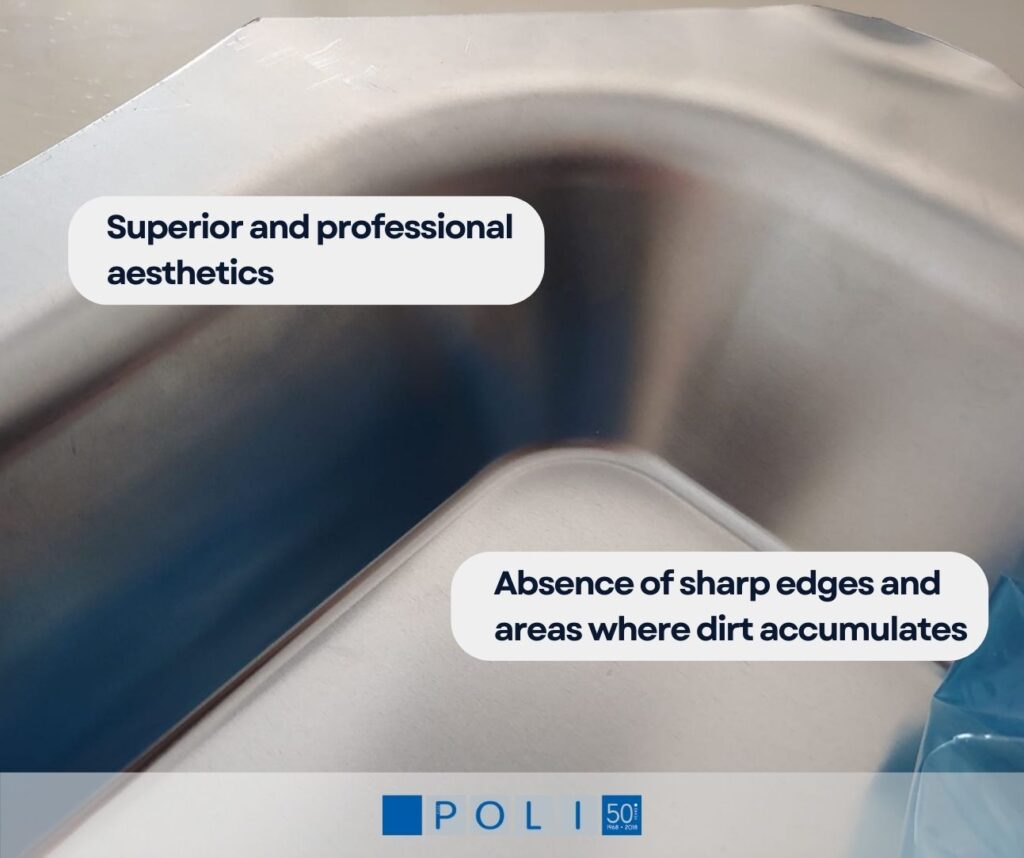

Furthermore, deep drawing reduces the thickness of aluminum to 1.5 mm, improving overall stability and product handling. In this way, the lunch box offers hygiene and ease of cleaning. The risk of dirt accumulation in folding points, corners, and welding areas is eliminated. A continuous and smooth surface, achieved through deep drawing, significantly reduces possible residues, improving the overall hygiene of the final product.

8 Benefits

With the new production method proposed by Fratelli Poli, the product can boast:

- Absence of sharp edges and dirt stagnation areas

- Professional and pleasing aesthetics that give the impression of excellence and professionalism

- Piece obtained through a single stamping, hence without welding or perforation defects

- Possibility to create appropriate ribs to make the tray more rigid

- Possibility to evaluate the use of thinner thicknesses with the same rigidity (with the insertion of ribs)

- Lower processing cost compared to current methods

- Higher processing quality (repeatability and finish) than current methods

- Possibility to anodize the entire piece to increase resistance to washing with chemical agents

The Result? A Shared Success

F.lli Poli’s story demonstrates that innovation can be fueled by collaboration. The introduction of new technologies and production methods, such as deep drawing stamping in the case of aluminum trays, was made possible thanks to the close partnership between the client and the supplier. The determination of both companies to build a relationship of trust and value has led to a shared success.

This story highlights the intrinsic value of F.lli Poli collaborating with its customers. In addition to creating quality products, the strength of a solid partnership can open doors to new opportunities, stimulate innovation, and ensure long-term success in the business world.

Tell us about your project.Write to us without obligation at info@fratellipoli.it and share your project with us. |